Our History

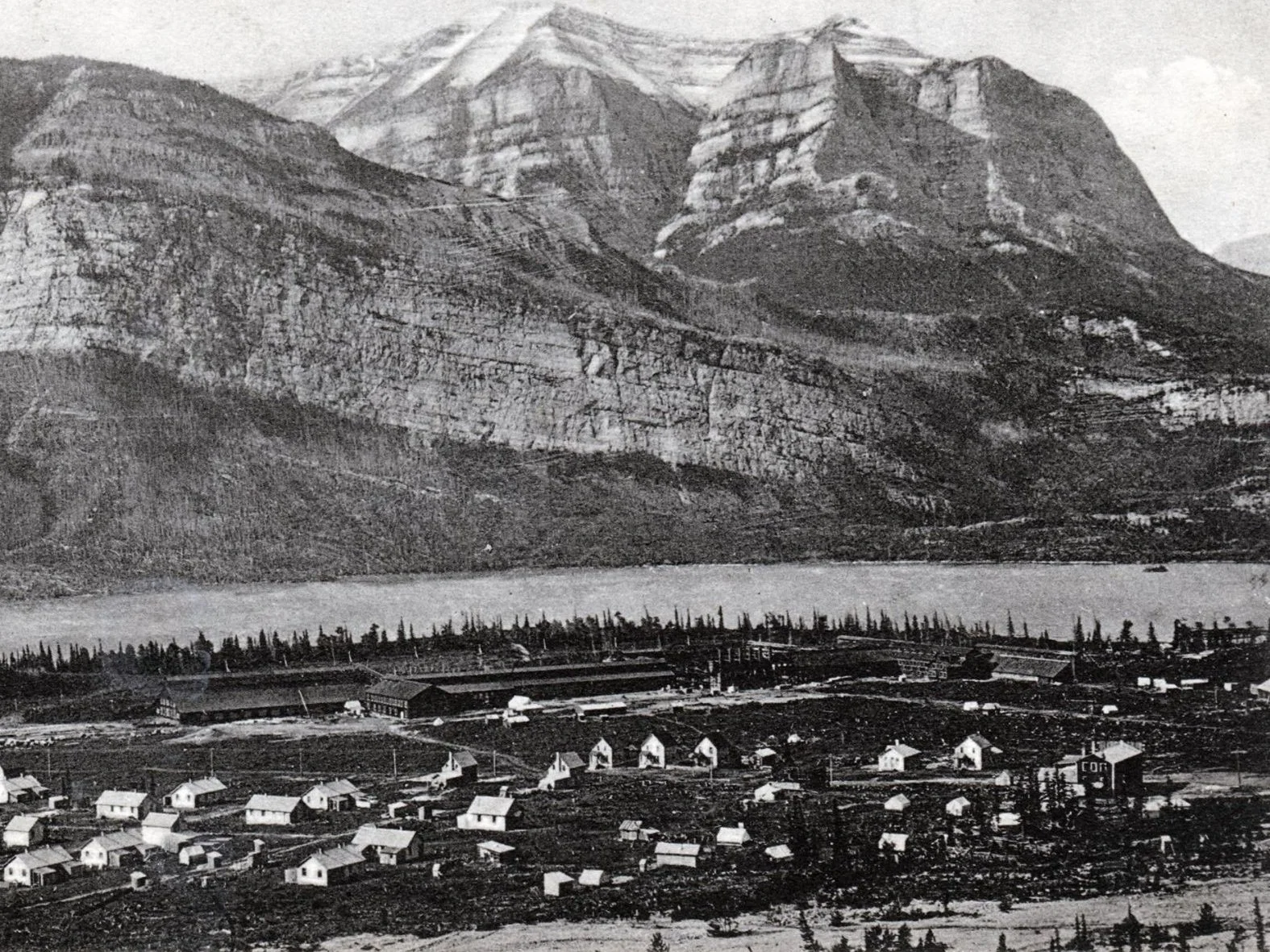

In 1906, the Western Canadian Cement

& Coal Company opened what would

become the most innovative and modern cement plant in the world.

Nestled at the edge of the Rocky Mountains, the Exshaw plant site was chosen for the abundant quantity and quality of limestone, nearby power sources, and proximity to the Canadian Pacific (CPR) rail line.

Images appear courtesy of The Canmore Museum

1906

Three hundred young men, some with their families, came from all over the world to build what would become Canada’s the largest industrial plant in the country.

When the plant was completed, some of the workers moved on, but others stayed for the opportunity They were attracted by the potential to work permanently at the plant and settle in the community of Exshaw.

1906

In the early days, rock blasting took place in the mountain above the plant. Rocks were hand loaded into small rail cars, which travelled downhill to the crushers, the grinders and then into the kilns. The plant produced between 1500-1800 barrels of Portland cement per day, using six 80-foot kilns.

1908

Slow markets, railway strikes and a flawed sales strategy caused the plant to close. Workers continued to quarry rock from the mountains above Exshaw, but that was the extent of the operations.

1909

The 1909 amalgamation of ten Canadian cement companies formed the Canada Cement Company. With that and new management, the Exshaw plant began to operate again.

1911

The completion of the Seebe dam provided inexpensive power to the plant and replaced the coal-fired steam generator that was built in 1906.

It Is What We Built:

The History of the Lafarge Exshaw Plant

Video courtesy of the Canmore Museum

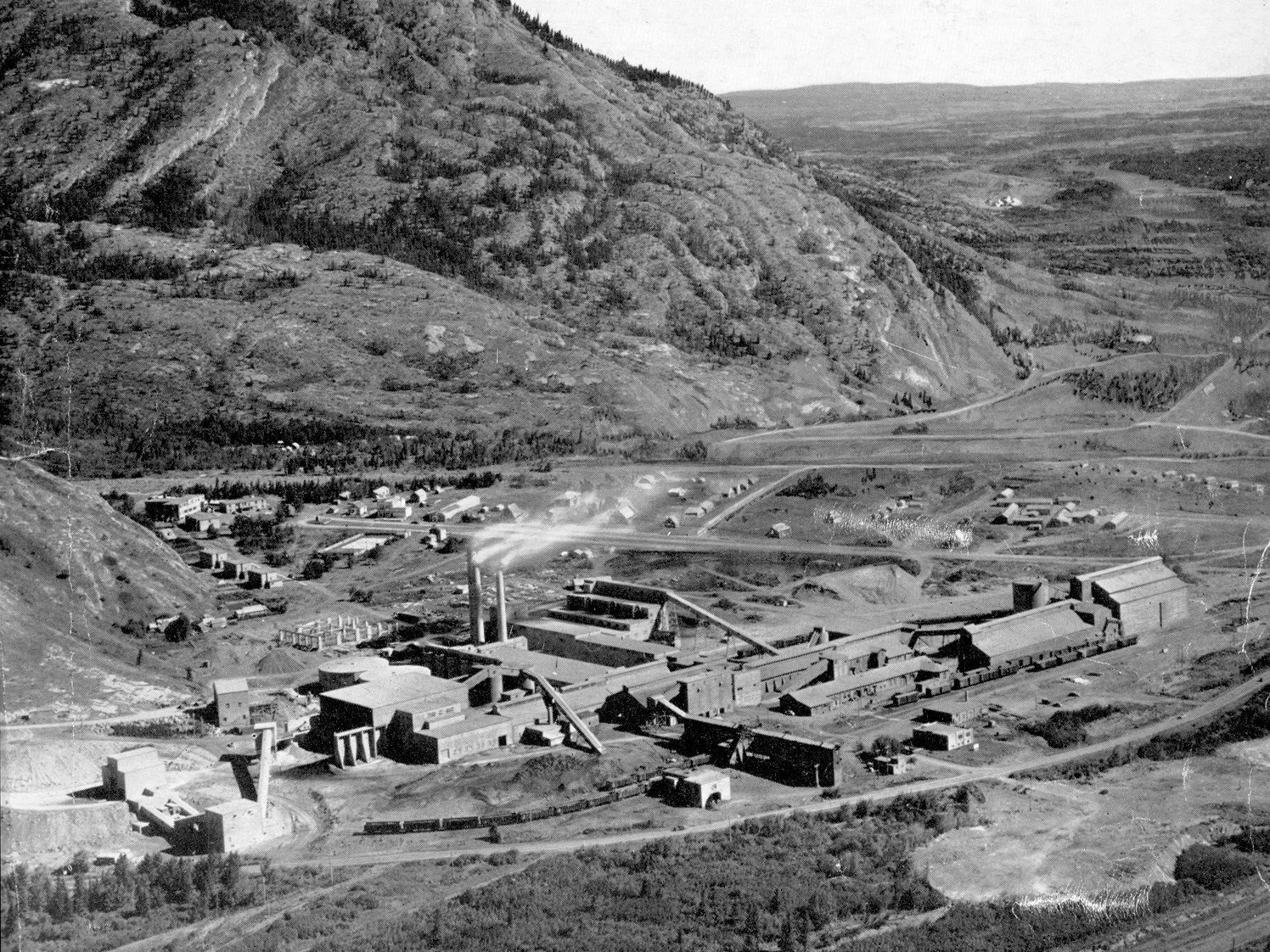

1912

Six old kilns were replaced with three more efficient 150-foot coal-fired kilns.

1920s

In the mid-1920s, post war modernizations led to a switch from blasting to hydraulic mining.

1940s

Exshaw switched from a dry manufacturing process to a wet process.

1951

Exshaw was the first company plant to convert from coal to natural gas-fired kilns.

1950s

Early in the decade, the plant introduced a new mountain top quarry and began using electric shovels, 30-tonne trucks and a mobile rotary drill.

1970

Canada Cement merged with Lafarge Canada to form Canada Cement Lafarge Ltd. This new company would become the largest supplier of cement in Canada and a major contributor to the development of Canada’s two fastest growing cities, Calgary and Edmonton.

Over the decade, much of the old plant was demolished and the expansion required the demolition of much of uptown Exshaw, including the elementary school, protestant church and 47 homes.

1988

Canada Cement Lafarge Ltd. became Lafarge Canada Inc.

2013-2016

Over this three-year period, more than $500 million was invested to modernize the plant.

2023

The Exshaw plant invested upwards of $30 million into lower carbon fuels.

2023-2030

More than $1 billion is forecasted to be spent on Carbon Capture and Sequestration (CCUS).